Understanding the Benefits of Solar Battery Storage Systems

Roadmap: How This Guide Helps You Bottle Sunshine

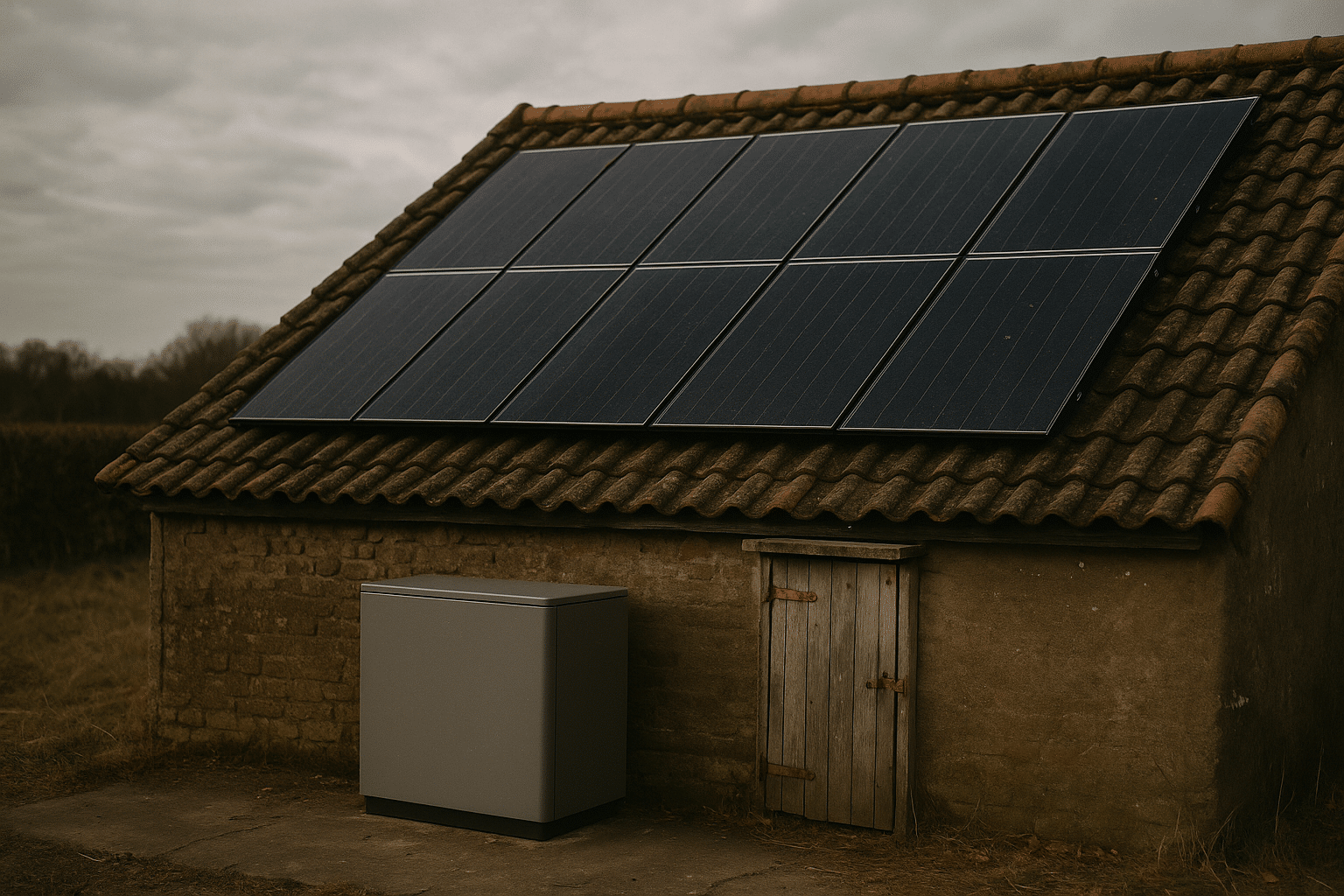

Before diving into components and chemistry, it helps to know where we’re headed. Solar-plus-storage is more than a rooftop array and a box of cells; it is a coordinated system that captures daytime surplus and returns it when you need it most. Think of photovoltaics as the harvest and batteries as the pantry—each valuable alone, but transformative together. This article begins with a concise outline so you can scan for what matters to you, then expands each part with data, examples, and practical comparisons you can use.

Outline of the journey ahead:

– Photovoltaic fundamentals: how panels convert light into electricity, efficiency metrics, and real-world output.

– Energy storage architectures: AC- and DC-coupled designs, sizing basics, and where round-trip efficiency is gained or lost.

– Battery technology landscape: chemistries, cycle life, safety trade-offs, temperature behavior, and recycling pathways.

– Designing for goals: self-consumption, backup, and bill management, with simple math and scenario-based examples.

– Conclusion and next steps: a short checklist to move from curiosity to a grounded plan.

Why this structure? Because decisions cascade. Roof orientation and inverter configuration influence how much surplus you can store; chemistry choice shapes available power, lifespan, and safety requirements; and local tariffs or incentives determine what “value” looks like for your home or business. We’ll keep the tone friendly and the numbers honest. You’ll see typical ranges—like module temperature coefficients or battery cycle life—that illuminate trade-offs without pretending one-size-fits-all. Wherever helpful, we’ll include bite-size lists and rules of thumb so you can evaluate proposals with confidence rather than guesswork.

What you’ll gain by the end:

– The vocabulary to decode quotes and spec sheets without a magnifying glass.

– A feel for how much energy your site could produce and store across seasons.

– Clarity on which storage topology and chemistry align with your goals and constraints.

– A straightforward path to action, from load profiling to permitting and future add-ons.

If energy is a story, solar-plus-storage is the plot twist that changes the ending. With the outline in mind, let’s explore how a beam of sunlight becomes reliable, nightly comfort—and how to make that outcome predictable rather than wishful.

Photovoltaic Fundamentals: From Sunlight to Usable Watts

Photovoltaic (PV) modules turn photons into direct current (DC) by exciting electrons in semiconductor layers. Modern monocrystalline modules commonly deliver module efficiencies around 19–23% under Standard Test Conditions (STC: 1,000 W/m², 25°C cell temperature, AM1.5 spectrum). Real roofs, however, live outside the lab. Under Normal Operating Cell Temperature (NOCT), heat raises cell temperature, and output drops according to the module’s temperature coefficient, often about −0.30% to −0.45% per °C above 25°C. On a hot summer day with 60°C cell temperature, it’s normal to see a 10–15% reduction compared to STC.

Orientation and tilt matter. In mid-latitudes, south-facing (north-facing in the southern hemisphere) with a tilt roughly equal to local latitude offers robust annual yield. East- and west-facing arrays shift production toward morning or late afternoon, sometimes increasing self-consumption even if yearly output is slightly lower. Shading from trees, chimneys, or neighboring structures can cause disproportionate losses by limiting current in series-connected cells, which is why module-level power electronics or carefully planned stringing can mitigate hotspots and energy loss.

How much energy can you expect? As a rule of thumb, 1 kW of well-sited PV might produce roughly 1,200–1,800 kWh per year depending on solar resource, climate, and system losses. Performance ratio (PR)—the fraction of theoretical yield that becomes delivered AC energy—typically falls between 0.75 and 0.90 when factoring in inverter efficiency, wiring, soiling, and temperature. Bifacial modules can add 5–15% in suitable settings by capturing reflected light, especially over bright surfaces or on elevated racking with good albedo.

Inverters perform maximum power point tracking (MPPT) to extract available energy as conditions change. Central, string, and micro approaches each have use cases: string inverters are simple and efficient; micro-level electronics can limit shade impacts and provide granular monitoring. DC-to-AC conversion typically exceeds 96% efficiency in modern equipment. In the context of storage, note that DC-coupled systems can avoid an extra conversion stage when charging batteries from PV, while AC-coupled systems may simplify retrofits and add placement flexibility.

Key PV takeaways you can use immediately:

– Shade and heat are the quiet adversaries; address them in design, not after installation.

– A slightly lower annual yield can still be advantageous if it aligns production with your consumption peaks.

– Monitoring matters; it reveals when washing panels or trimming foliage pays back in real kWh.

With realistic expectations for generation, you are ready to consider how storage captures value from every sunny hour—especially the ones you aren’t home to use.

Energy Storage Architectures: Turning Daylight into Nighttime Certainty

Solar generation peaks at midday, while many households and businesses peak in the evening. Batteries bridge that gap. A storage system is defined by capacity (kWh), power (kW), allowable depth of discharge (DoD), C‑rate (charge/discharge rate relative to capacity), round‑trip efficiency (RTE), and control strategy. Typical stationary lithium systems report RTE around 90–95% under moderate temperatures; lead-acid often lands near 70–85%; flow systems vary from about 65–80% depending on configuration.

Two primary topologies dominate: AC-coupled and DC-coupled. AC-coupled storage places a battery inverter on the AC side, making retrofits straightforward and allowing placement flexibility and modular scaling. However, PV energy may go DC→AC→DC→AC when charging and discharging, adding conversion losses. DC-coupled storage ties the battery on the DC bus with the PV array and a hybrid inverter, which can reduce conversion steps and slightly improve efficiency during direct PV charging. It is common to see DC coupling favored for new builds and AC coupling for upgrades, though local code requirements and layout logistics often tip the decision.

Use cases shape design:

– Self-consumption: Store midday surplus to offset evening loads and limit exports where credits are modest.

– Backup power: Keep essential circuits—refrigeration, lighting, communications—running during outages; design for islanding via automatic transfer and anti-islanding compliance.

– Time-of-use arbitrage: Charge when rates are low or solar is abundant; discharge at peak pricing to trim the bill.

– Demand charge management: In commercial settings, discharge during short, high-power spikes to reduce monthly demand fees.

Right-sizing is part art, part arithmetic. Start with a 24-hour load profile, paying attention to the evening ramp. For example, a home averaging 20 kWh per day with a prominent 5–9 p.m. peak might pair a 5–7 kW PV array with a 10–14 kWh battery to cover most evening consumption in fair weather. In outage-focused designs, consider the power draw of priority loads: a 4–6 kW continuous output battery can sustain essentials, but electric heating or large air conditioners may require higher power or selective load shedding.

Thermal management and location influence both safety and lifespan. Batteries prefer temperate environments; prolonged exposure below freezing can limit charging, while high heat accelerates degradation. Enclosures with ventilation or passive cooling extend service life. In grid-connected systems, smart controls prioritize objectives—bill savings, resilience, or export limits—while responding to weather forecasts and utility signals. When constraints like limited roof area or strict interconnection rules apply, creative combinations—east/west arrays, modest oversizing, and carefully set export caps—often unlock strong performance without costly upgrades.

With a storage topology and purpose in mind, the next question becomes: which chemistry delivers the durability, safety profile, and cost structure that aligns with your plan?

Battery Technology Landscape: Chemistries, Trade-offs, and Where They Shine

Battery chemistry determines how your system behaves across safety, lifespan, temperature, energy density, and price. In stationary solar applications, several families are common, each with strengths worth matching to a specific goal.

Lithium iron phosphate (LFP) has gained wide adoption for residential and commercial storage thanks to robust thermal stability and long cycle life. Typical energy density ranges from about 90–160 Wh/kg, lower than some alternatives, but less critical in stationary settings. Well-managed LFP packs often deliver 3,000–7,000 cycles to around 80% remaining capacity, with round-trip efficiency near 90–95% and a comfortable operating window. Cold-weather charging still needs care, and calendar aging proceeds slowly when kept at moderate state of charge and temperature.

Nickel-rich lithium chemistries such as NMC or NCA offer higher energy density—commonly 150–220 Wh/kg—which is valuable where space is tight. They can provide strong power performance but may exhibit faster capacity fade under high depth-of-discharge or elevated temperatures relative to LFP. Cycle life often lands in the 1,000–3,000 range depending on depth of discharge, thermal conditions, and management. For stationary systems prioritizing compactness, they remain viable, though thermal controls and conservative operating windows become important.

Lithium titanate (LTO) trades energy density for exceptional power handling and cycle life. With fast charge capability, wide temperature tolerance, and cycle counts that can exceed 10,000 in some stationary profiles, LTO suits high-throughput use cases like demand charge management. Its lower energy density and typically higher cost per kWh limit adoption in space-constrained residential systems, but its durability appeals to certain commercial and microgrid deployments.

Lead-acid remains a known quantity with approachable upfront cost. Flooded, AGM, and gel variants differ in maintenance and cycle life, with many systems delivering roughly 300–1,000 cycles at 50% depth of discharge. Round-trip efficiency is usually lower than lithium, and deep cycling shortens life. Still, where budgets are tight, ambient conditions are mild, and discharge rates are modest, lead-acid can be a pragmatic stepping stone.

Flow batteries, including vanadium redox designs, separate energy and power: tanks define energy (kWh), while cell stacks define power (kW). This architecture scales elegantly for long-duration storage, with cycle life that can exceed 10,000 and minimal capacity fade when properly maintained. Round-trip efficiency often ranges from about 65–80%, and energy density is low, making them better for larger footprints where duration matters more than compactness.

Emerging options like sodium-ion target cost resilience and improved cold-weather performance. Early commercial systems suggest energy density below most lithium-ion but promising supply-chain flexibility. Zinc-based chemistries and metal-air variants are also advancing, particularly for long-duration niches. Across all chemistries, smart battery management systems (BMS), conservative charge windows, and moderate temperatures are the universal levers that protect cycle life.

How to choose?

– Prioritize safety and longevity for homes: LFP is widely regarded for stationary use due to thermal stability and durable cycling.

– Need compactness or higher discharge power in a small space? Nickel-rich lithium chemistries can fit, with careful thermal design.

– Seeking high-throughput or harsh environments? LTO and certain flow systems offer resilience, though often at higher cost or footprint.

– Tight budgets and modest cycling? Lead-acid can serve, with realistic DoD limits and regular maintenance where applicable.

End-of-life and sustainability also matter. Lead-acid benefits from mature recycling. Lithium-ion recycling is expanding, recovering materials like nickel, cobalt, and lithium, and second-life applications are emerging for packs retired from higher-stress roles. Specify take-back commitments and inquire about local recycling partners to keep useful materials in circulation.

Designing, Valuing, and Safeguarding Your Solar-Plus-Storage System

With PV generation, storage topology, and chemistry options in view, the final step is turning ideas into a right-sized system that performs reliably for years. Start by mapping your energy story: a 15-minute interval load profile over a few representative months tells you when you use power, how deeply evenings dig into the grid, and which appliances define your peaks. Then align PV output to that curve, targeting a production-to-load ratio that achieves high self-consumption without chronic curtailment.

A quick sizing example: Suppose your site averages 24 kWh/day with a 6–9 p.m. peak of 3 kW. A 6–8 kW PV array could generate roughly 7,200–12,000 kWh/year depending on location and system losses. To shift evening demand, a 10–13 kWh LFP battery with 5 kW of discharge power could cover typical nights, assuming moderate weather. If resilience is the priority, list critical loads and their wattage (refrigerator ~150 W average with surges, networking ~20 W, select lighting ~100 W, gas furnace fan ~400 W). Sum them and ensure the battery’s continuous and surge ratings, plus inverter capacity, can deliver headroom during motor starts.

Economics hinge on tariffs and incentives. Time-of-use spreads of $0.20–$0.40/kWh between off-peak and peak can make arbitrage compelling. Where export credits are modest, self-consumption gains matter more than gross production. Many regions offer rebates, performance-based incentives, or tax credits which can reduce upfront costs. When evaluating payback, model degradation—assume, for instance, 2–3% annual PV performance loss from soiling and aging if uncleaned, and gradual battery capacity fade based on the chosen chemistry. Consider maintenance: occasional panel cleaning in dusty climates, firmware updates, and visual inspections for wiring and conduit integrity.

Safety is non-negotiable. Follow applicable electrical codes and spacing guidelines, provide clear labeling and disconnects, and keep batteries in ventilated, temperature-moderated locations. For indoor installations, discuss fire detection and containment strategies with your installer, including keeping required clearances from living spaces and ignition sources. In outage-ready setups, verify islanding operation through regular, supervised tests so you know exactly which circuits stay powered and for how long.

Future-proofing reduces regret. Leave space for additional battery modules, specify enough inverter capacity for potential EV charging or heat pump adoption, and consider communication protocols that enable participation in virtual power plants. Smart controls that use weather forecasts and tariff schedules can squeeze extra value by charging ahead of storms or discharging during coincident peaks. In commercial settings, add demand-charge analytics and submetering to target the few minutes each month that set your fee structure.

Summary for action:

– Gather interval load data and list critical circuits.

– Size PV for high self-consumption; choose AC or DC coupling based on retrofit needs and efficiency goals.

– Match chemistry to use case: durability and safety for homes, power density or throughput for specialized needs.

– Model economics with realistic losses, degradation, and incentives; plan maintenance and monitoring.

– Reserve capacity for future loads and grid services where available.

Conclusion and next steps: With a clear grasp of how photovoltaics, storage architectures, and battery chemistries interact, you can commission a system that delivers dependable evening comfort, quieter outage rides, and measurable bill savings. The path from sunlight to certainty is straightforward when each component is selected to serve your specific goals—and when the whole is orchestrated to behave like one thoughtful machine.